Page 194 - G7_2021_WEB_pendiente

P. 194

THREAD LINE

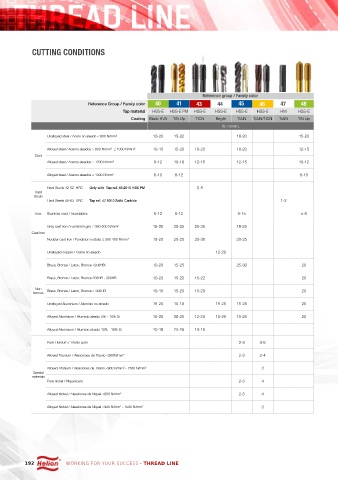

CUTTING CONDITIONS

Reference group / Family color

Reference Group / Family color 40 41 43 44 45 46 47 48

Tap material HSS-E HSS-E PM HSS-E HSS-E HSS-E HSS-E HM HSS-E

Coating Black HVA TiN Up TiCN Brigth TiAlN TiAlN/TiCN TiAlN TiN Up

Vc m/min.

Unalloyed steel / Acero no aleado ≤ 800 N/mm 2 10-20 15-22 18-20 15-20

Alloyed steel / Aceros aleados > 800 N/mm 2 ≤ 1000 N/mm 2 10-15 15-20 15-20 18-20 12-15

Steel

Alloyed steel / Aceros aleados ≤ 1200 N/mm 2 8-12 10-18 12-15 12-15 10-12

Alloyed steel / Aceros aleados ≤ 1300 N/mm 2 6-10 8-12 8-10

Hard Steels 42-52 HRC Only with Tap ref. 43.2010 HSS PM 3-5

Hard

Steels

Hard Steels 48-63 HRC Tap ref. 47.9010 Solid Carbide 1-2

Inox Stainless steel / Inoxidables 6-12 8-12 8-15 5-8

Grey cast iron / Fundición gris ≤ 350-500 N/mm 2 15-20 20-25 20-35 18-25

Cast Iron

Nodular cast iron / Fundicion nodular ≤ 300-400 N/mm 2 15-20 20-25 20-30 20-25

Unalloyed copper / Cobre no aleado 12-20

Brass, Bronze / Laton, Bronce <200HB- 10-20 15-25 25-30 20

Brass, Bronze / Laton, Bronce 200HB - 300HB 10-20 15-22 15-22 20

Non

ferrous Brass, Bronze / Laton, Bronce > 300HB 10-15 15-20 15-20 20

Unalloyed Aluminium / Aluminio no aleado 15-25 10-18 15-25 15-25 20

Alloyed Aluminium / Aluminio aleado 2% - 10% Si 15-20 20-25 12-20 15-25 15-25 20

Alloyed Aluminium / Aluminio aleado 10% - 15% Si 10-18 20-25 10-15

Pure Titanium / Titanio puro 2-3 3-5

Alloyed Titanium / Aleaciones de Titanio <900N/mm 2 2-3 2-4

Alloyed Titanium / Aleaciones de Titanio <900 N/mm 2 - 1500 N/mm 2 3

Special

materials

Pure nickel / Niquel puro 2-3 4

Alloyed Nickel / Aleaciones de Niquel <900 N/mm 2 2-3 4

Alloyed Nickel / Aleaciones de Niquel <900 N/mm 2 - 1500 N/mm 2 3

192 WORKING FOR YOUR SUCCESS · THREAD LINE