What is Trochoidal milling?

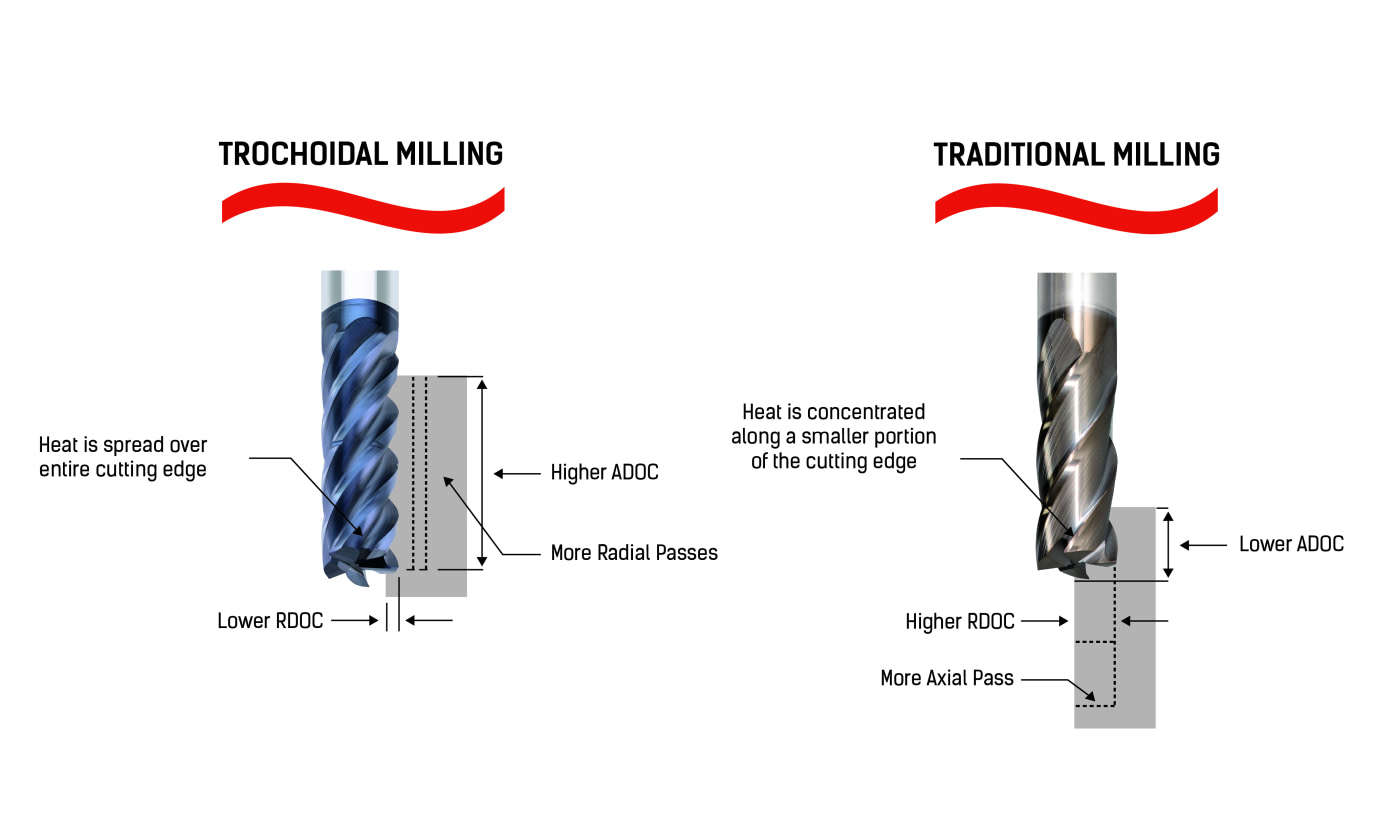

Trochoidal milling is a method of machining that takes advantage of high speeds while maintaining a low radial depth of cut (RDOC) and a high axial depth of cut (ADOC) to create a slot wider than the cutting tool’s cutting diameter. This is accomplished using a series of circular cuts known as a trochoidal tool path.Instead of a completely linear radial tool path in conventional machining, trochoidal milling follows a spiral tool path with a low RDOC to reduce load and wear on the tool.

Which are the advantages of Trochoidal Milling?

-

Decreased cutting forces

- Reduced heat

- Greater machining accuracy

- Improved tool life

- Faster cycle times

- One tool for multiple slot sizes

You can see more information in our catalogue!

Check out also our video: