The aluminum milling process has specific characteristics. On the one hand, aluminum is one of the most demanded materials at an industrial level because it is quite ductile and moldable, and can be easily alloyed with other materials.

On the other hand, aluminum is easy to mill, although although aluminum milling is easier than other materials, it is necessary to pay attention to the technique. Both aluminum and its possible alloys with other materials are soft and easy to cut. Even so, it is essential to have a well-polished, balanced and stable tool to obtain maximum performance and to be able to print speed in the cut.

What is the milling process?

Milling is a technique that allows cutting materials such as aluminum, steel, iron or wood to make finished or semi-finished parts, depending on the machining process in which it is included.

The process that this milling follows is widely used in the industry to obtain specific pieces of these materials. Increasingly, it is part of automated machining processes to carry out series of parts and large volumes of industrial production.

How is aluminum milling done?

Although it seems a simple task due to the properties of the material, it is necessary to pay attention to the tool to carry out this type of cut, since the milling of aluminum reaches a high speed.

Choosing the correct cutter is essential to control the cutting process and to be able to correctly evacuate the chips, given the speed with which waste material is generated. If the cutter does not have a lip that allows the chips to be released, this will hinder the cut and the efficiency of the entire process will be lost.

Differences between milling aluminum and other metals

A differential characteristic is that the material itself increases the edge, so it is difficult to control the milling process and the milling machine can easily become unbalanced.

The possibilities of alloying the material mean that it may lack the desirable uniformity for easy cutting. It is necessary to pay attention to the possible effects to choose the correct cut and include it within the planning of the machining.

H2- Characteristics Milling cutters for aluminum

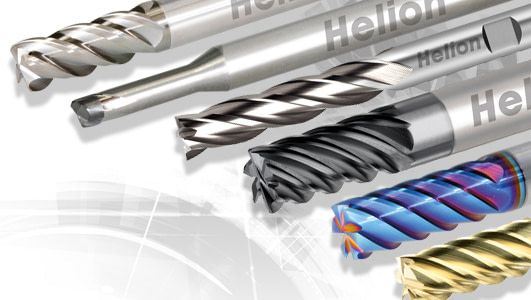

The characteristics of aluminum milling are based on the design of the tool, which can be adapted to better control the efficiency of the process. Optimum milling cutters can be created with the right characteristics to deal with the properties of aluminum and its possible alloys, such as through aluminum milling drills.

There are specific milling cutters, for example aeronautical parts, capable of avoiding the heating of the tool and with interchangeable systems of the steel inserts of the milling cutters to be able to carry out the process at a high speed, thus avoiding the build-up of the edges and favoring the Chip evacuation in aluminum milling processes.

Benefit from the experience and track record of our expert professionals in aluminum milling at Helion Tools.