Page 17 - FRESAS X PULGADAS.indd

P. 17

INCH LINE INCH LINE

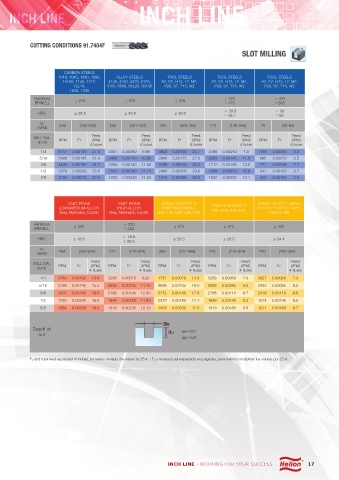

CUTTING CONDITIONS 91.7404F

SLOT MILLING

CARBON STEELS

1018, 1040, 1080, 1090, ALLOY STEELS TOOL STEELS TOOL STEELS TOOL STEELS

10L50, 1140, 1212, 4140, 4150, 4320, 5120, A2, D2, H13, L2, M2, A2, D2, H13, L2, M2, A2, D2, H13, L2, M2,

12L15, 5150, 8630, 86L20, 50100 P20, S7, T15, W2 P20, S7, T15, W2 P20, S7, T15, W2

1525, 1536

Hardness ≦ 275 ≦ 375 ≦ 375 > 375 > 475

BRINELL ≦ 475 ≦ 655

HRC ≦ 28.5 ≦ 39.8 ≦ 39.8 > 39.8 > 50

≦ 49.1 ≦ 65

Vc 440 (352-528) 252 (201-303) 320 (256-384) 170 (136-204) 70 (56-84)

(SFM)

Feed Feed Feed Feed Feed

MILL DIA. RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM)

(inch)

4 flutes 4 flutes 4 flutes 4 flutes 4 flutes

1/4 6757 0.00100 27.0 3081 0.00080 9.86 4933 0.00120 23.7 2568 0.00010 1.0 1081 0.00005 0.2

5/16 5406 0.00145 31.4 2465 0.00110 10.85 3946 0.00175 27.6 2054 0.00145 11.9 865 0.00073 2.5

3/8 4505 0.00190 34.2 2054 0.00140 11.50 3289 0.00230 30.3 1712 0.00190 13.0 721 0.00095 2.7

1/2 3379 0.00250 33.8 1541 0.00190 11.71 2466 0.00300 29.6 1284 0.00250 12.8 541 0.00125 2.7

5/8 2703 0.00310 33.5 1233 0.00240 11.83 1973 0.00390 30.8 1027 0.00320 13.1 432 0.00160 2.8

CAST IRONS CAST IRONS STAINLESS STEELS STAINLESS STEELS(PH)

(LOW&MEDIUM ALLOY) (HIGH ALLOY) (FREE MACHINING ) STAINLESS STEELS 13-8 PH,15-5PH,17-4PH,

304, 304L,316,316L

Gray, Malleable, Ductile Gray, Malleable, Ductile 304, 416,420F,430F,440F Custom 450

Hardness > 220

BRINELL ≦ 220 ≦ 260 ≦ 275 ≦ 275 ≦ 325

> 18.8

HRC ≦ 18.8 ≦ 26.6 ≦ 28.5 ≦ 28.5 ≦ 34.4

Vc

(SFM) 284 (356-534) 272 (216-324) 390 (312-468) 270 (216-324) 250 (200-300)

Feed Feed Feed Feed Feed

MILL DIA. RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM)

(inch)

4 flutes 4 flutes 4 flutes 4 flutes 4 flutes

1/4 3460 0.00100 13.8 3298 0.00070 9.20 4757 0.00070 13.3 3298 0.00060 7.9 3027 0.00060 7.3

5/16 2768 0.00140 15.5 2638 0.00105 11.10 3806 0.00105 16.0 2638 0.00085 9.0 2422 0.00085 8.2

3/8 2307 0.00180 16.6 2198 0.00140 12.30 3172 0.00140 17.8 2198 0.00110 9.7 2018 0.00110 8.9

1/2 1730 0.00240 16.6 1649 0.00180 11.90 2379 0.00180 17.1 1649 0.00140 9.2 1514 0.00140 8.5

5/8 1384 0.00300 16.6 1319 0.00230 12.10 1903 0.00230 17.5 1319 0.00180 9.5 1211 0.00180 8.7

Depth of ae=1xd1

cut ap

ap=1xd1

F and total feed expressed in inches, for metric multiply the values by 25.4. / F y avance total expresado en pulgadas, para métrico multiplicar los valores por 25,4.

z

z

INCH LINE · WORKING FOR YOUR SUCCESS 17