Page 16 - FRESAS X PULGADAS.indd

P. 16

INCH LINE

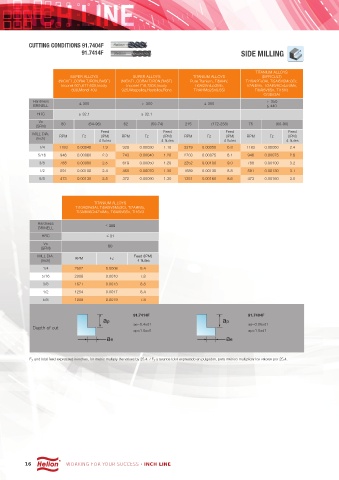

CUTTING CONDITIONS 91.7404F

91.7414F SIDE MILLING

TITANIUM ALLOYS

SUPER ALLOYS SUPER ALLOYS TITANIUM ALLOYS (DIFFICULT)

(NICKEL,COBALT,IRON,BASE) (NICKEL,COBALT,IRON,BASE) Pure Ttanium, Ti6Al4V, Ti10Al2Fe3Al, Ti5Al5V5Mo3Cr,

Inconel 601,617,625,Incoly Inconel 718,750X,Incoly Ti6Al2Sn4Zr2Mo, Ti7Al4Mo, Ti3Al8V6Cr4Zr4Mo,

800,Monel 400 925,Waspalloy,Hastelloy,Rene Ti4Al4Mo2Sn0.5Si Ti6Al6V6Sn, Ti15V3

Cr3Sn3Al

Hardness ≦ 300 > 300 ≦ 350 > 350

BRINELL ≦ 440

HRC ≦ 32.1 ≦ 32.1

Vc 80 (64-96) 62 (50-74) 215 (172-258) 75 (60-90)

(SFM)

Feed Feed Feed Feed

MILL DIA. RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM) RPM Fz (IPM)

(inch)

4 flutes 4 flutes 4 flutes 4 flutes

1/4 1183 0.00040 1.9 929 0.00030 1.10 3379 0.00050 6.8 1183 0.00050 2.4

5/16 946 0.00060 2.3 743 0.00040 1.20 2703 0.00075 8.1 946 0.00075 2.8

3/8 788 0.00080 2.5 619 0.00050 1.20 2252 0.00100 9.0 788 0.00100 3.2

1/2 591 0.00100 2.4 465 0.00070 1.30 1689 0.00130 8.8 591 0.00130 3.1

5/8 473 0.00130 2.5 372 0.00090 1.30 1351 0.00160 8.6 473 0.00160 3.0

TITANIUM ALLOYS

Ti10Al2Fe3Al, Ti5Al5V5Mo3Cr, Ti7Al4Mo,

Ti3Al8V6Cr4Zr4Mo, Ti6Al6V6Sn, Ti15V3

Hardness ≦ 300

BRINELL

HRC ≦ 31

Vc

(SFM) 60

MILL DIA. RPM Fz Feed (IPM)

(inch) 4 flutes

1/4 2507 0.0008 8.4

5/16 2008 0.0010 7.8

3/8 1671 0.0013 8.8

1/2 1254 0.0017 8.4

5/8 1008 0.0019 7.8

91.7414F 91.7404F

ap ap

Depth of cut ae=0.4xd1 ae=0.05xd1

ap=1.5xd1 ap=1.5xd1

F and total feed expressed in inches, for metric multiply the values by 25.4. / F y avance total expresado en pulgadas, para métrico multiplicar los valores por 25,4.

z

z

16 WORKING FOR YOUR SUCCESS · INCH LINE