Positioning: selection and applications

In machine tapping, it is important to select the type of entry to ensure the duration of the tool and the perfect finish of the thread. Depending on the material to be threaded and the type of hole, blind or through, the type and shape of the entry will be chosen.

In general, for through holes, the form B geometry is used, which pushes the chip in the forward direction, while in blind holes using spiral taps, the chip is directed backwards, in the opposite direction to the advance.

In both cases, care is taken that the chip does not interfere with the correct cutting of the thread. Use very short leads such as form E only when it is necessary to drive the thread to the bottom of the blind hole.

To ensure well-formed threads, it is essential to take into account the previous holes.

|

IMAGE |

FORM |

|

Blind Hole |

|

Through Hole |

|

Application and Chamfer forms to DIN 2197 |

||

|

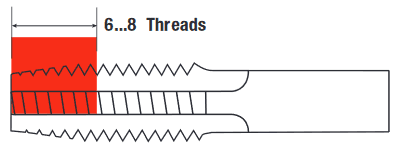

Form A |

|

Long, 6 - 8 threads for short through holes |

|

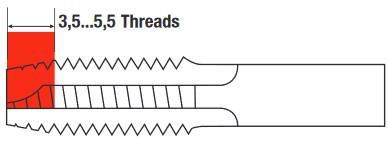

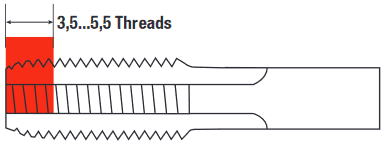

Form B |

|

Medium, 3.5 - 5.5 threads, with spiral point, for all through holes and deep tapping holes in medium and long-chipping materials |

|

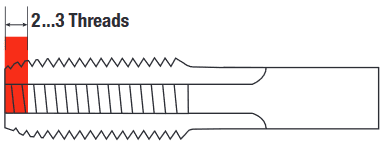

Form C |

|

Short, 2 - 3 threads for blind holes and generally for aluminium, grey cast iron and brass |

|

Form D |

|

Medium, 3.5 - 5 threads for short through holes |

|

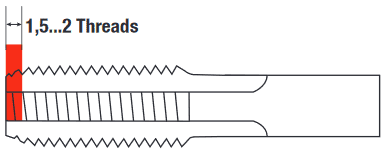

Form E |

|

Extremely short, 1.5-2 threads, for blind holes with little run-out depth. |