NC spotting drills

When producing accurately positioned holes, holes with close diameter tolerances, deep holes or generally with unfavourably shaped workpieces (round, rough. etc.) it’s recommended to use a NC spotting drill. This ensures the following drill, drills accurately and prevents the drill from running off.

NC spotting drills can also be used to produce chamfers or countersinks (when using a spot drill with a larger diameter than the actual hole) and centring in one operation.

NC spotting drills are designed with a very short flute length and without body clearance to ensure a very rigid design and therefore accurately positioned spotting. Due to the design, NC spot drills are only suitable for spotting, drilling depths must not exceed the length of the point geometry.

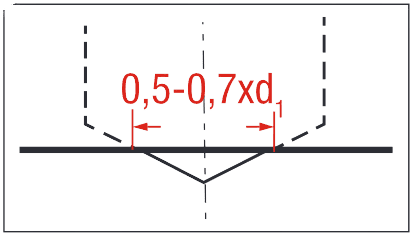

Selecting an NC spotting drill

Ideally, the spotting diameter should be chosen between 0.5 to 0.7xD.

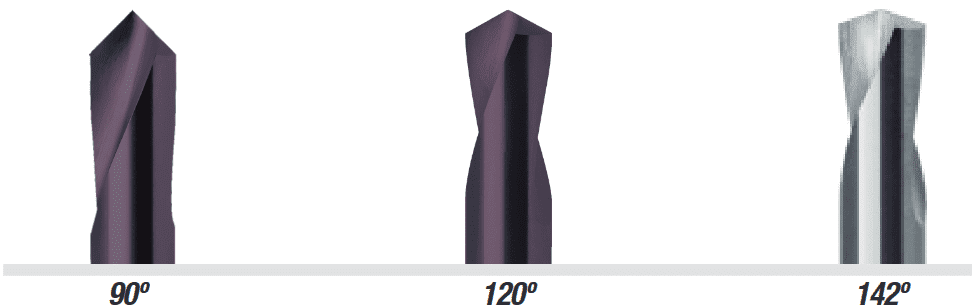

90º NC spotting drills

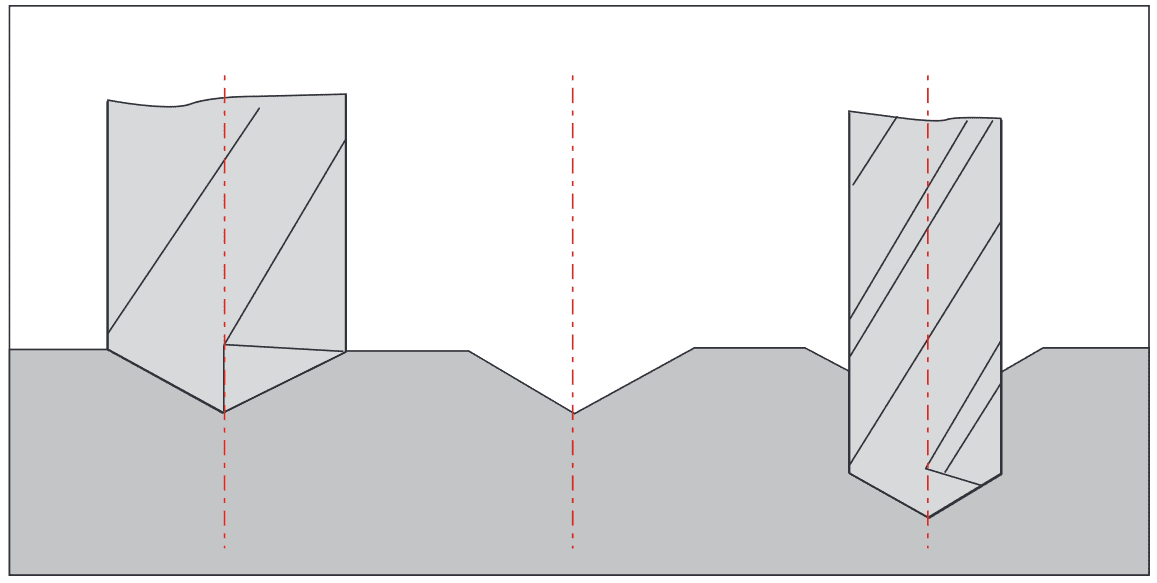

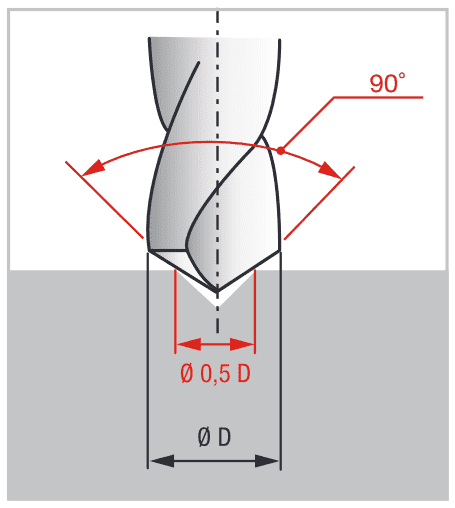

NC spotting drills with a 90º point angle are ideally suited for spotting if the following HSS/ HSCO drills have a relatively large diameter edge. This ensures that the following HSS/ HSCO drill drills with the cutting flute first and is guided by the most stable points of the cutting edge.

In addition, NC spotting drills with a 90º point angle are used to produce a 90º countersink and centre in one operation if the spotting diameter is larger than the actual hole diameter.

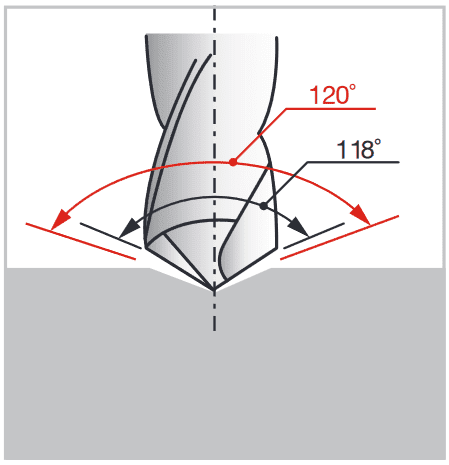

120º NC-spotting drills

NC-spotting drills with a 120º point angle are specially suited for spotting operations if the actual hole is subsequently produced with HSS/HSCO drills with a 118º point angle. This ensures the following HSS/HSCO drill spots with the point first and is well guided.

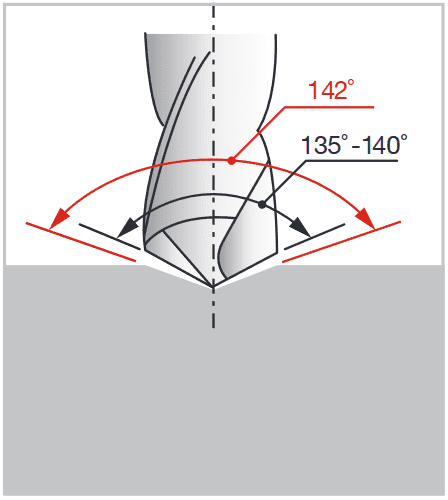

142º NC-spotting drills

NC-spotting drills with 142º point angle are specially suited for spotting operations if the actual hole is subsequently produced with carbide drills with a 135º - 140º point angle. This ensures the following carbide drill spots with the point first, centers and is well guided. If the cutting corners of the carbide drill meet the material to be machined before the point, there is the risk of corner crumbling with carbide drills.

NC spotting drills