Milling formulas

|

Description |

Formula |

Definition |

|

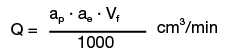

Chip volumes over time |

|

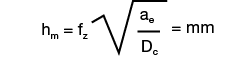

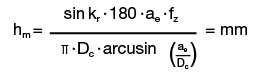

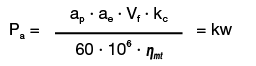

Dc= Cutting diameter ae= Radial cutting width ap= Axial cutting depth fz= Tooth feed rate De= Effective cutting diameter vc= Cutting speed Q = Chip volumes over time I = Working length Vf= Feed rate speed hm= Average chip thickness kr= cut entering angle Pa= Driving power kc= Specific cutting force ηmt = Level of efficiency Tc= Processing time |

|

Average chip thickness (Face and step milling) when ae / Dc ≤ 0.1 |

|

|

|

Driving power |

|

|

|

Average chip thickness when ae / Dc ≥ 0.1 |

|

|

|

Processing time |

|